Don’t Wait for Failure to Learn What Went Wrong

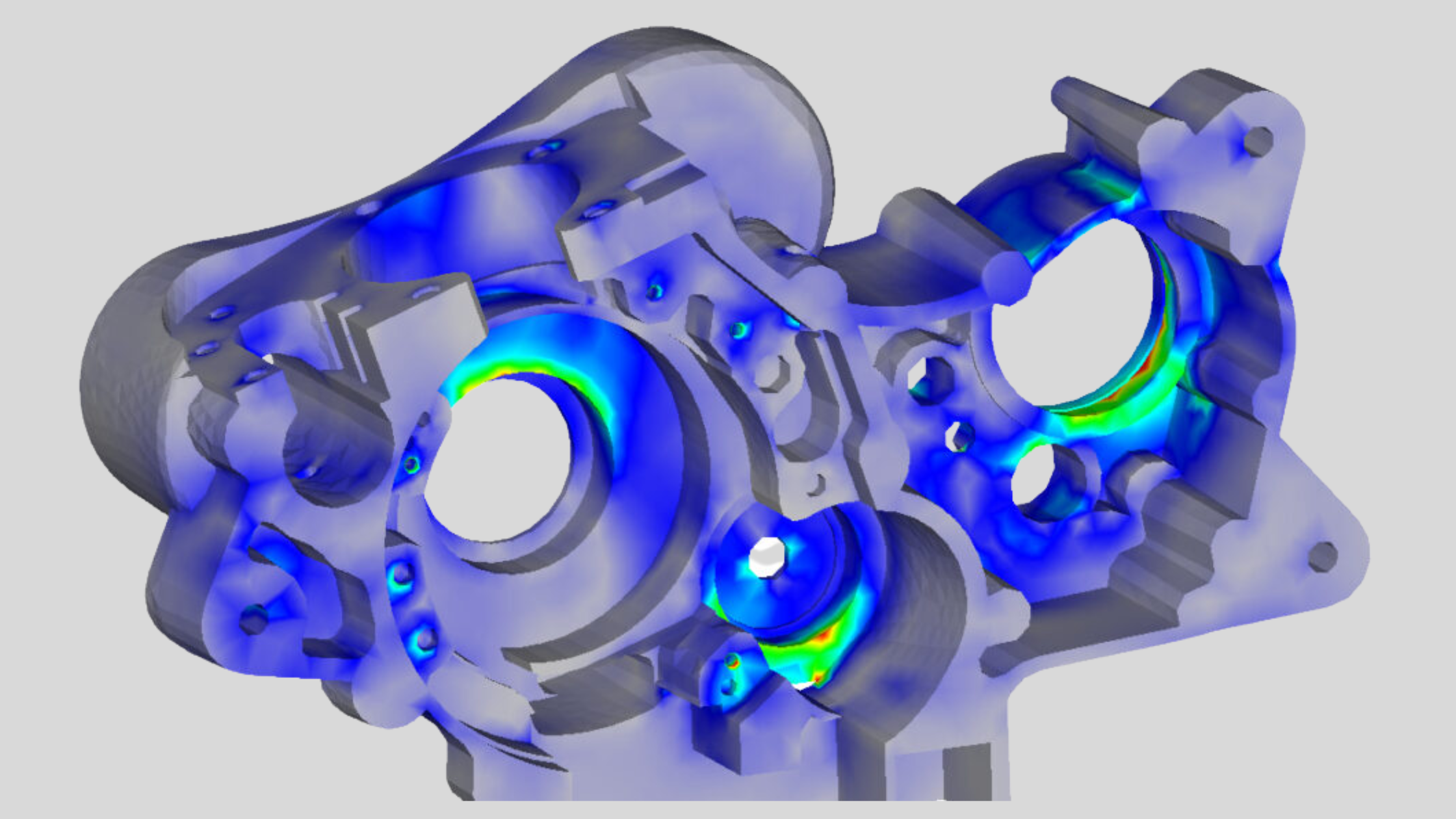

For engineering teams in Los Angeles, CA, where industries like aerospace, automotive, and clean tech push design boundaries daily, accuracy matters. Complex assemblies often come with hidden risks—joint fatigue, part distortion, and stress concentrations that don’t show up in static hand calcs. That’s where finite element analysis software makes a difference.

With simulation tools like Siemens Simcenter 3D, engineers can evaluate the behavior of individual parts and full assemblies under load. From bolted joints to welded frames, you can catch weak points before they show up on a test rig.

Validate, Optimize, Repeat

Finite element analysis software in Los Angeles, CA helps engineers validate whether a design will work—but it also helps improve it. Once you’ve confirmed your part survives, you can trim material, reduce weight, and explore other configurations without starting from scratch.

When time-to-market is often the deciding factor, this ability to simulate and iterate quickly is a serious advantage.

Engineering Confidence Without Overdesign

FEA tools do more than reduce guesswork—they give engineers confidence to build leaner designs without compromising safety. That can lead to lighter products, fewer materials, and fewer test failures down the road.

At SDA Software, we support engineering teams in Los Angeles, CA and across the United States with simulation training, workflow integration, and technical support for Siemens finite element analysis software. Learn more at www.sdasoftware.com or call 1-703-935-2832.